-40%

Silicon Iron B FM .550 in Dia. x 12" used for solenoid switches, armatures,relay

$ 3.38

- Description

- Size Guide

Description

Silicon Iron B FM .550 in Diameter x 12"used for :

solenoid switches, armatures, pole pieces, relays, etc.

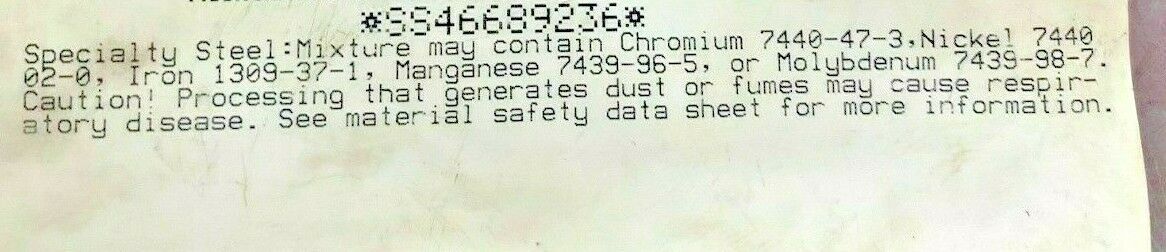

Composition (Nominal)

0.03 C, 0.40 Mn, 2.50 Si, 0.12 P, Bal. Fe

Improved machining characteristics over "B" grade are being obtained by using this modified free-machining alloy with no sacrifice in magnetic properties.

Specifications: ASTM A867 Alloy 2F

Description

CarTech Silicon Core Iron "B-FM" is melted in electric arc furnaces to exacting chemical specifications and carefully controlled through all manufacturing processes to produce a fine-grain, uniform quality magnetic core iron.

This alloy exhibits improved machining characteristics over CarTech Silicon Core Iron "B". Improvements in machinability of up to 40% have been realized on automatic screw machines.

In addition, CarTech Silicon Core Iron "B-FM" displays lower residual magnetism, higher electrical resistivity, and is more magnetically soft when heat treated under identical conditions than CarTech Silicon Core Iron "B".

The magnetic characteristics and cold working/cold forming properties of CarTech Silicon Core Iron "B-FM" are in the same range as CarTech Silicon Core Iron "B".

Applications

CarTech Silicon Core Iron "B-FM" has been used in solenoid switches, armatures, pole pieces, relays, etc.

This alloy should be considered for use in applications requiring a magnetic core component superior to mild steel, magnetic iron (99.2% Fe minimum) and a 1% silicon core iron.

Properties

Physical Properties

Specific Gravity

--

7.69

Density

--

0.2760

lb/in³

Mean CTE

77 to 750°F

7.35

x 10-6 in/in/°F

Electrical Resistivity

70°F

240.7

ohm-cir-mil/ft

Curie Temperature

--

1470

°F

Magnetic Properties

Magnetic properties are determined in accordance with ASTM A341.

Diameters less than 1" (25.4 mm) are determined on a 10" (25.4 cm) long specimen on a Fahy Permeameter. Diameters 1" (25.4 mm) are larger are evaluated on solid ring specimens machined from a disc.

Specimens are annealed at 1550°F (843°C) two hours in a wet hydrogen atmosphere and furnace cooled at a rate of 100°F (55.6°C) per hour to 1000°F (538°C) and any cooling rate thereafter.

DC Hysteresis

Normal DC Magnetization Curves

Saturation Flux Density

--

20600.0

G

Coercivity

--

0.700

Oe

Maximum Permeability

--

5000.00

Residual Induction

--

5500

G

Treatment for Final Closed Pack Anneal

--

1550

°F

Typical Mechanical Properties

Typical Mechanical Properties

Heat Treatment

Items as supplied from the mill are not in the most magnetic soft condition, nor are they supplied to magnetic property requirements. As supplied magnetic property requirements must be approved by the mill.

Finish fabricated parts must be heat treated to achieve soft magnetic characteristics. Suggested heat treating atmosphere is a wet hydrogen atmosphere in the temperature range of 1550/1600°F (843/871°C), two to four hours at temperature and cooled at a rate of 100/200°F (38/93°C) per hour to 1000°F (538°C) and any rate thereafter.

Other heat treating atmospheres can be employed, such as nitrogen-hydrogen combinations, vacuum, exothermication and inert atmosphere retort. Resulting magnetic characteristics will not be as good as the wet hydrogen atmosphere, which provides the best degree of decarburization.

Other heat treatment temperatures in the range of 1350°F (732°C) to 1900°F (1038°C) can be employed to achieve certain advantages such as brazing and fine grain size as required by end application. A sacrifice in certain magnetic characteristics will be realized. A dry atmosphere must be employed at 1750°F (954 °C) and above.

Workability

Cold Working

Cold working and cold forming properties are of the same order as the non-free-machining Silicon Core Iron "B" (2.5% silicon core iron). Only thin machine sections (less than 1/16" [1.60 mm]) thick can be formed.

Machinability

Following are typical feeds and speeds for Silicon Core Iron "B-FM".

Machinability Tables

Additional Machinability Notes

Figures used for all metal removal operations covered are average. On certain work, the nature of the part may require adjustment of speeds and feeds. Each job has to be adjusted for best production results with optimum tool life. Speeds and feeds should be increased or decreased in small steps.

Other Information

Applicable Specifications

ASTM A867 Alloy 2F

Forms Manufactured

Bar - Many forms and conditions (Note: cold drawn bar available in diameters 1/2" [12.7 mm] or less)

Bar-Rounds

Billet

Strip

Technical Articles

A Designer's Manual On Specialty Alloys For Critical Automotive Components

A Simplified Method of Selecting Soft Magnetic Alloys

Development of Chrome Core® 13FM Stainless - A Soft Magnetic Stainless Steel

Soft Magnetic Alloys with Improved Corrosion Resistance

Soft Magnetic Ferritic Stainless Steels for Electromechanical Devices

Unless otherwise specified, registered trademarks are property of

CRS Holdings Inc., a subsidiary of Carpenter Technology Corporation.

Copyright 2019 CRS Holdings Inc. All rights reserved.